940 - 4.0-Inch Remote Control Monitor

940 - 4.0-Inch Remote Control Monitor

The first entry in our range of mid-sized remote control cannons, the 940 Remote Control Super-Low-Profile Monitor can flow up to 3,500 GPM. The 940 enjoys the balance and ease of movement as its smaller cousins and is built for years of constant use.

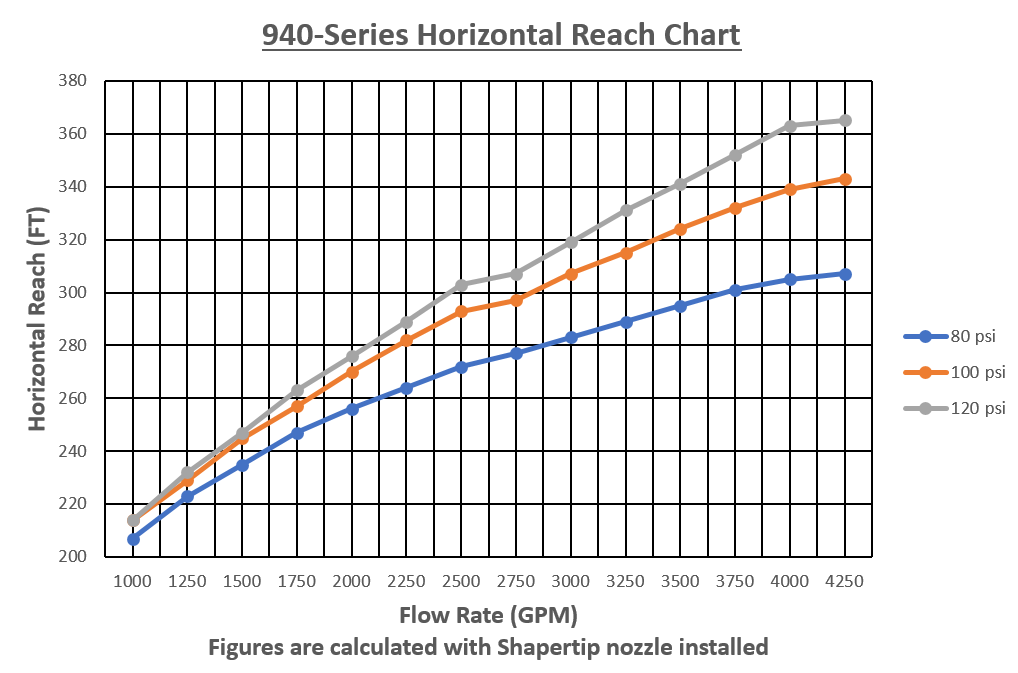

The 940 Remote Control Super-Low-Profile Monitor (RCM) is perfectly adaptable to most any application. This unit is equally at home on a fireboat or an oil refinery where remote manipulation is necessary. Delivering up to 3,500 GPM more than 350-feet, the 940 RCM is used where there is a large source of fuel for potential fires, such as found in petrochemical plants and offshore vessels. The standard 940 RCM is controlled via a tethered control box with a single joystick. Options include nozzle and valve controls, as well as true wireless and Bluetooth control signals. Full programming is also available from basic oscillating sweeps to complex movements and cycles, offering semi-autonomous operation. Electric and hydraulic power options are offered. Monitor control software for your smart phone or tablet are now available!

TECHNOLOGY

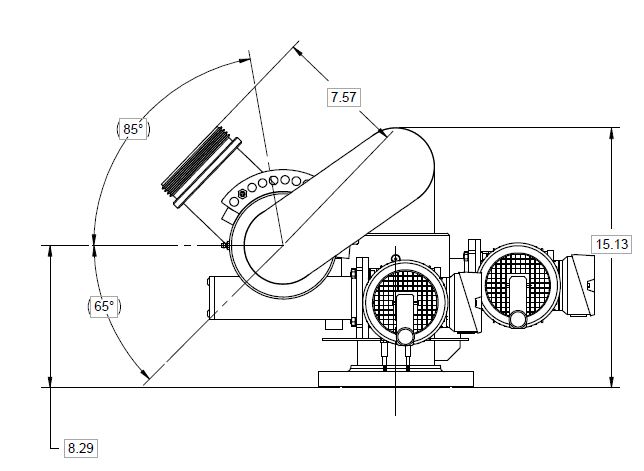

Rated for severe duty, the 940 RCM is durable enough for the task at hand. Using U.S. sourced smooth bore Schedule 40, 4.0-inch diameter piping, the 940 RCM consists of three sections: the intake base, lower ell, and the upper ell. The intake base is available in many configurations and provides the foundation for the first swivel, the horizontal axis swivel. This swivel rotates 340° and houses the first of two industrial electric motors. The upper ell incorporates the vertical swivel, second motor and monitor outlet. The vertical swivel has a +/- range of 85°/65°. Using movable environmentally sealed proximity sensors, each swivel’s travel can be easily adjusted to fit your specific application.

TYPICAL CONFIGURATION

4.0" RCM SLP Monitor, 125/220VAC, 4.0" Raised Face Flange Inlet, 4.0" NH Outlet, Proximity Switches, 304 Stainless Steel, Red

Note: New installations require a monitor control module and starter panel.

OPTIONS

POWER

Electric AC with multiple voltages available (explosive atmospheres certification available)

Hydraulic (low pressure)

INLET

4.0” raised or flat face 150# ANSI flange

6.0” raised or flat face 150# ANSI flange

8.0” raised or flat face 150# ANSI flange

Custom threads or flanges available

OUTLET

2.5” NH thread (NST)

4.0” NH thread (NST)

4.0” raised face 150# ANSI flange

Custom threads or flanges available

SWIVEL BRAKES

Physical hard stops

Electric proximity switches (explosive atmospheres certification available)

MATERIAL

304 stainless steel

316 stainless steel

316L stainless steel

FINISH

Powder coat red internally & externally

Hand polished

Custom powder coat colors available

CONTROLS

All options below can be ordered for multiple monitor control and with custom programming.

• Tethered (single monitor control)

• Tethered w/Remote Fog Nozzle Controls (single monitor control)

• Tethered w/Water Valve Controls (single monitor control)

• Tethered w/Remote Fog Nozzle & Water Valve Controls (single monitor control)

• Wireless

• Bluetooth (apps available for your smart phone and tablet, too!)

FEATURE LIST

• Super-low-profile upper waterway design

• 340° horizontal rotation

• 150° vertical range

• Four adjustable proximity (limit) switches

• Very well balanced

• Each swivel has two rows of stainless steel ball bearings for stability and easy of motion

• Two zerk fittings on both swivels for easy maintenance

• Industrial powder coating for corrosion and abrasion protection, applied internally and externally

• Robust, hand welded joints

• Simple, intuitive control system

• Easily replaceable motors and switches

• Options for remote nozzle and water valve controls

• Hydrostatically tested to 300 PSI for 5-minutes, minimum