2.5" Station Monitor

2.5" Station Monitor

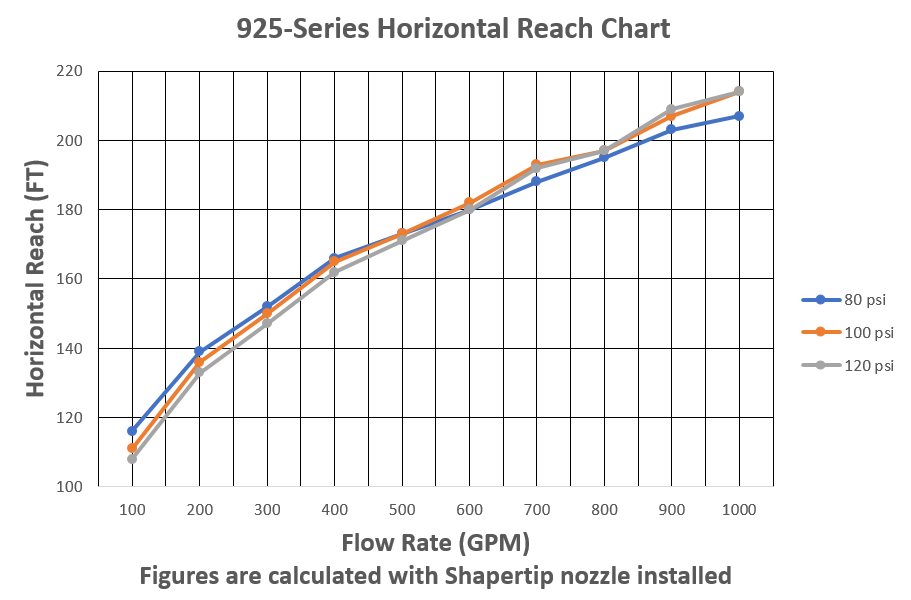

Stang’s bestselling monitor, the 925 Station Monitor hits that sweet spot between capability and cost. Able to throw a stream of water over 200-feet, the 925 will securely manage up to 1000 GPM. The 925 combines the world class, hand-made construction and performance of all Stang guns.

The 925 Station Monitor is a jack-of-all-trades. This monitor is comfortable operating on trucks, trailers, boats, industrial plants and refineries, stock yards, ship yards, mining sites, basins – you name it. The 925 fills the need of most applications because it can manage flow rates between 150-1000 GPM with as little as 50 PSI, or as much as 150. In addition, the 925 Station is available with the widest variety of options and accessories of any Stang cannon, making it truly versatile and adaptable to most any job.

TECHNOLOGY

Stang’s manufacturing approach is grounded in tradition and attention to detail, and the 925 Station Monitor is where this philosophy is displayed. Using high-quality, seamless, 2.5-inch diameter schedule 40 piping, the 925 consists of three sections: the intake base, lower ell, and the upper ell. The intake base is available in many configurations and provides the foundation for the first swivel, the horizontal axis swivel. This swivel rotates a full 360-degrees and is very well balanced. The lower ell makes a 90° turn into the upper ell, which incorporates the vertical swivel and Stang’s proprietary (and legendary) curved waterway. The vertical swivel has a +/- range of 85°/45° and is designed to spin clean while under pressure even with the weight of a heavy brass nozzle. Available with either two lock knobs or Bladelock friction brakes, it’s obvious why everyone loves the 925.

OPTIONS + UPGRADES

OUTLET

2.5” NH (Male) Thread

*Custom threads or flanges available

HANDLE

Tiller bar

C-handle

P-handle

SWIVEL BRAKES

Dual Lock Knobs

Blade Lock w/Lock Knob Combo

PRESSURE GAUGE*

0-300psi Pressure Gauge w/ Guard

*available upon request

WATERWAY MATERIAL CHOICES

Carbon Steel

Stainless Steel (304)

Stainless Steel (316)*

*available upon request

FINISH

Powder Coat ‘Fire Safety Red’

Polished (stainless steel only)

*Custom powder coat color available upon request

FEATURE LIST

• Heavy duty build

• Lightweight

• Small footprint

• Full 360° horizontal rotation

• 130° total vertical range

• Each water tight swivel has two rows of stainless steel bearings for stability and ease of motion

• Two zerk fittings on both swivels for easy maintenance

• Industrial powder coating for corrosion and abrasion protection

• Durable, hand-welded joints

• Hydrostatic Pressure tested to 300 PSI for 5-minutes, minimum